Make wires connecting the world.

The heating resistor wire itself is fabricated from a high-resistance material. That means the material does not conduct electricity easily through it. As electricity runs through the wire, it encounters that resistance, which creates heat in the wire. Many different applications can benefit from this heat. We can use this heat to heat up some liquid, melt up some metals, or dry some materials. Heating resistor wire creates heat, making it a useful instrument in several conditions.

TS Heating Alloy Heating resistor wire has a wide application range in many sectors, having many important functions. It is commonly found in the food industry in equipment that heats and cooks food. The ovens and food warmers, for example, depend on this type of wire to ensure our food is cooked and heated properly. In the medical industry, machine sterilizes tools and equipment using Resistance Wire. This is crucial to keep things safe for patients and be cleaned up. In the aerospace field, this wire is employed to heat airplane engines. This helps the engines function, which is especially necessary in the cold, and keeps planes flying safely.

It has many benefits if we use heating resistor wire. For this reason, it is one of the main advantages, one that is cost-effective for producing heat. That means you are not paying a huge amount of money to use it and it is very resource efficient. One more benefit is that we can simply manage how much heat the cable produces. This means we can control the heat to our liking. Another important thing is that heating resistor wire is highly robust material. It's expensive for businesses to have to keep doing repairs, so it can last a long time with very little maintenance.

That said, there are some cons worth mentioning about TS Heating Alloy heating resistor wire. Safety is one of the top concerns. Improper use of wire is dangerous. For instance, hot or leaking wiring can lead to fires or even explosions if it contacts flammable materials. That is why following safety guidelines is extremely important. Another reason is that the wire can heat a lot due to its high resistance. This energy can be more difficult to keep in check in some cases, and if left unattended, can lead to issues.

Here are some of the key factors that you would have to take into account when choosing a proper TS Heating Alloy heating resistor wire. The first consideration is the substance of the wire. Resistance varies with the materials, and this is why the resistance value plays a role in how much heat we generate. Certain materials, for instance, may generate more heat than those with distinct properties. The size or diameter of the Fe-Cr-Al Wire, as well as how long it is, almost as much to do with how much heat is produced. A thicker wire can generate more heat (then a thin one).

It is very important that the wire matches the electricity that is currently being used. Either wire will become dangerous by having sparks and fires, and in situations when wire is inefficient in its field of work. Thus, always verify that the wire is suitable for your system.

Regular inspections are an important step to ensure the safety and efficacy of heating resistor wire systems. That just means inspecting the Ni-Chrome Wire every now and then for any signs of wear and tear. Replace them immediately to prevent accidents if you find any damage on the wires. Maintaining the equipment will help make sure the equipment continues operating properly and safely.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.

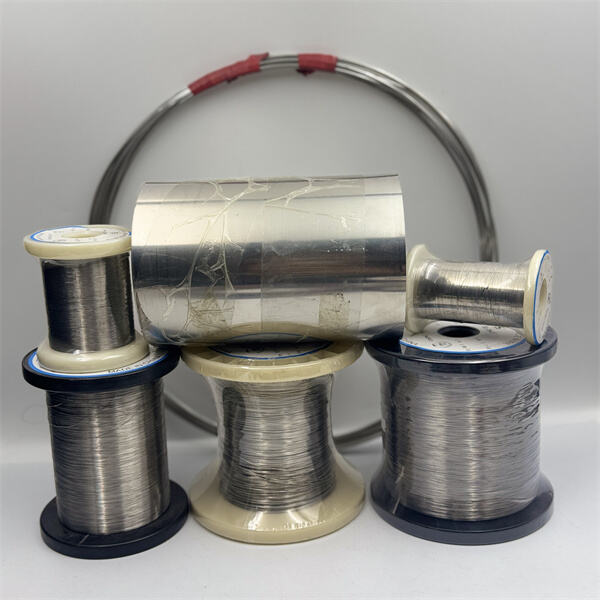

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.