Make wires connecting the world.

When we charge our devices phones and tablets we plug them into the wall using power cables. These cables play a crucial role in transmitting electricity from the outlet to our devices. But there is something else interesting about these cables: they can restrict the flow of electricity. This is called resistance. Resistance can influence the efficiency of our devices and lead to wasted energy. In this lesson we will learn about power cable resistance what is it what problems it presents to our devices how it is measured what can affect it and how we solve these problems in order to save energy.

We can measure and test resistance if we mentioned the TS Heating Alloy Power cable. This resistive wire device pushes a small amount of electricity through the cable and measures how much voltage drops due to resistance. Less resistance is a good thing; in order to achieve higher resistance the reported voltage will be lower and in order to make the system work better the reported voltage will be lower.

When electricity flows along a power cable, it encounters resistance. This resistance causes some of the electrical energy to be converted into heat, which we lose. The greater the resistance, the more energy lost, and the less effective our devices become. On the downside, if too much energy is dissipated, the cable can begin to heat up, which is hazardous and can even cause fires. It is crucial to keep our cables cool to ensure safety and power efficiency.

We use multimeter to measure the resistance in a TS Heating Alloy power cable This tool is very helpful! It applies a small amount of electricity through the cable and tracks how much voltage is lost due to resistance. If the voltage reading is low, that means the cable has low resistance, which is good. This enables our devices to function properly and conserve energy.

The amount of resistance that a power cable has can vary due to many different factors. Temperature is one important factor. Resistance increases as the temperature of a cable rises. In other words cables operating in hot conditions will resist more therefore be less efficient. A second consideration is how thick the cable is. Thinner cables tend to have higher resistance because they offer less room for the electricity to move. We want to make sure that we select the length of wire and resistance for our application because thicker cables can also often be more expensive and less flexible.

Choosing the proper cables and setting them up at the appropriate lengths can assist with power cable resistance and use energy more cleanly. They can make a huge difference in efficiency by choosing cables that have a lower resistance and by making them thick enough for the job. Furthermore length of wire resistance by TS Heating Alloy need to be installed correctly so they are tight but not damaged. It can contribute to lower resistance and better performance of our devices. Using high-heat rated cables in hot environments can also improve resistance and minimize energy loss.

Energy saving is vital and we are very well aware of how crucial power cable resistance is. This is the reason behind our manufacturing of low resistive and high quality heating cables that runs amazing. Our resistor wire are designed with the latest tech and materials to provide you with effective heating solutions for a variety of scenarios. Whether you need to heat pipes melt snow on roofs or warm up floors we have the right cable for you.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.

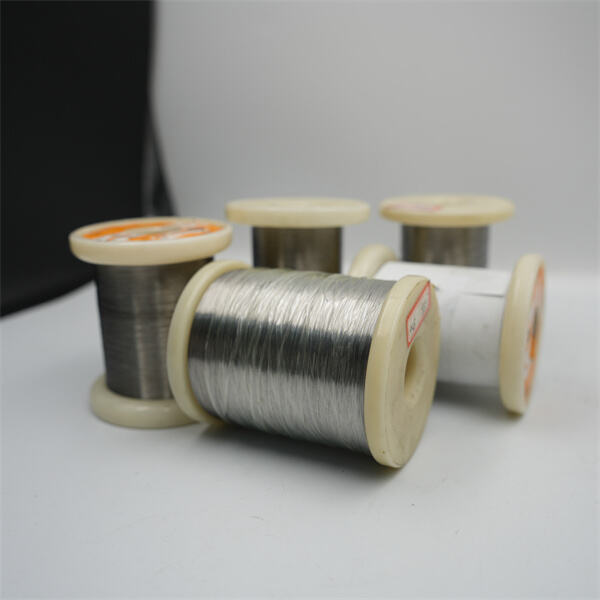

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.