Make wires connecting the world.

A resistance wire is an essential part of a device that we have on a daily basis. These wires allow things to get heated up and set the temperature for devices such as toasters, ovens, and even hair dryers! When you push the button on a toaster, it’s the resistance wires that heat up and turn your bread brown and crunchy. Do you know that there are various types of resistance wires, and they serve different purposes and have unique properties?

For one, Kanthal being a common type of resistance wire. Kanthal is of Iron, Chromium & Aluminum. This type of wire allows for the sustained high temperature needed for thermal cycle operations without degrading. Kanthal retains its shape even at high temperatures. And that’s why you’ll often find Kanthal wires in the heating elements of the machinery in larger machines, such as industrial furnaces, where extreme heat is needed to do the work.

Stainless steel high heat wire is likewise a common option for resistance heating. It’s made from a steel-chromium alloy. One of the major characteristics of stainless steel wires is their strength and durability which makes them a lasting material and enables them to withstand an excessive amount of use without wearing out.

So that means resistive wire and you are still restricted to whatever types of resistance wires you have. These wire are also great and very high temperature which makes them suitable for industrial applications.

This is a most resistor wire essential element to keep in mind, dealing with resistance wires in electrical devices. Whether you currently own an electrical appliance that makes use of electrical resistance wires or plan on purchasing one, you need to ensure that you take good care of them.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.

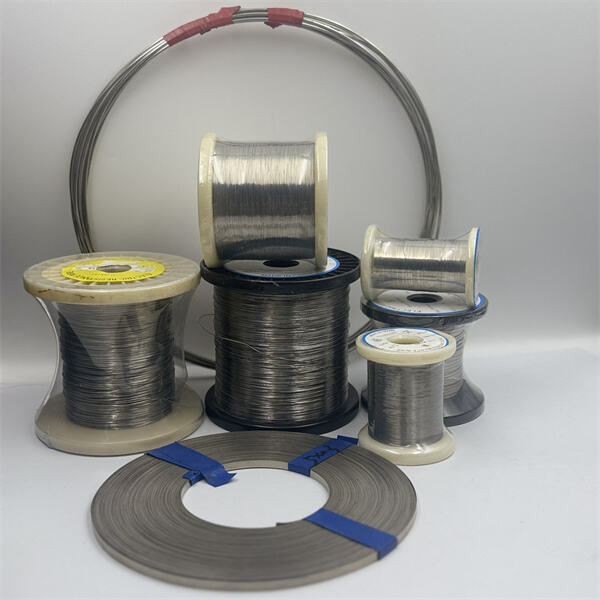

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.