Make wires connecting the world.

At TS Heating Alloy, we recognize the importance of proper public safety when it comes to electrical systems. That means a lot of details that we need to get right to make all work seamlessly and safely. A significant aspect of safety is ensuring that wire size to use is suitable to how much electricity that we will use. One special term that is used just for Resistance Wire is wire gauge, which describes how thick the wire is. This is signified by a number, and it is absolutely crucial to grasp this. The larger the number, the thinner the wire. Because if you see a small number, the wire is thick, and if you see a big number, the wire is thin

It's also worth noting that the gauge of the wire can affect how much current you can push through it. Larger numbers correspond to the thinner wires, which are more resistant. This means it’s harder for them to let electricity pass from one end to the other. It may help to think of resistance as a thin avenue of travel causing a bottleneck for cars moving through. As the number of cars grow, it becomes harder for these vehicles to move around. That is why we want thicker wires when we need to carry more electricity over long distances. If we anticipate a high amount of electricity, we should always use a thicker wire. It prevents issues and maintains the security of everything.

Picking the Fe-Cr-Al Wire size isn't literally picking any wire. This varies greatly based on things like the length of the wire, the amount of current going through it, and what type of circuit. The National Electric Code gives us guidelines so we know what the proper sizes for wires are. It gives several rules of thumb on size as well as charts of size for what voltage and current will be used. These rules help in ensuring that we are using the appropriate wire size that helps in smooth functioning.

When we run electricity through a Ni-Chrome Wire, it generates resistance. Wires are made of materials that create friction that resists the current, making it more difficult for the electricity to move through them. Watch what happens when either a toy car or a toy truck is pushed on a carpet. Electricity will encounter resistance, the longer the wire. It is the reason we should be using thicker wires at longer distances. This decreases the resistance and ensures that the electricity moves properly through. This is critical to remember when we are designing and installing electrical systems. If the wire gauge is insufficient or the distance is too long, the circuit will not work. This can lead to problem, and safety can be compromised.

Using the correct size of wire for DIY electrical projects is essential for both safety and function. The initial step in selecting the correct wire gauge is to define how much electricity the wire will need to transport. This will give you a sense of how thick the wire needs to be. When you have this, you can check to wire gage charts to determine for your purposes which size to purchase. These charts are real handy as they give you various wire gauge with amp rating they can carry safely.

Consider the length of wire the vehicle must travel as well. If a wire will have to run a long way, it’s always best to select a thicker wire than you think will be needed. So, this way you can make sure that enough power is making it to the end of the wire without losing anything on the way. When in doubt, always go with the thicker wire.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.

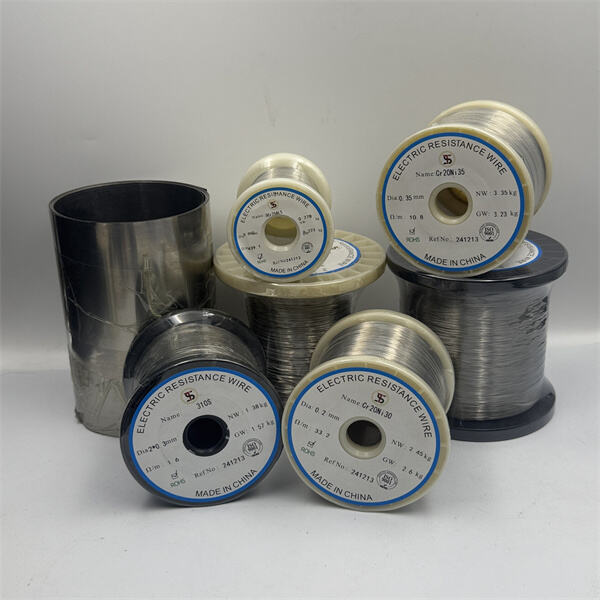

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.