Make wires connecting the world.

A bond wire has electrical flow through a fine wire that connects two sections of an electronic device. Bond wires are extremely thin (not much thicker than a human hair) to fit into the small spaces inside the device. These special TS Heating Alloy Resistance Wire are made from metals that are great for carrying electricity, such as gold or copper. As such, this is relevant as the materials must be capable of conducting electricity well for the device to work optimally.

Length and thickness of a bond wire are among one of the factors that influence the performance of an electronic device. Also, a longer wire has more resistance than a short one, so it slows the flow of electricity even further. Conversely, a thicker wire has greater conductivity, which means electricity will flow more easily. This is why engineers need to think hard when designing their devices. Wire length and wire thickness must be optimized to find a good trade-off between low LED curvature resistance and minimal LED performance, as well as heat conversion of the LEDs.

Temperature is another influential factor that can affect the performance of a device. The metal in the bond insulated resistance wire can expand, so it can change size when electronic devices heat up. The resistance can increase or decrease as a function of temperature. Unfortunately, not only when this resistance peaks, the device will no longer work, but can also cause a serious damage. And this is why engineers have to think about how heat will impact the materials they use.

The bond wire must therefore be selected in terms of material and dimension, as Engineers will want to minimize the resistance of the bond wire. They frequently use computers to handle simulations and experiment with various designs. It helps them discover what works best for their device even before they create it. By applying computer models to test the potential physical design of the wires, they will be able to evaluate how the lengths and the sizes will ultimately impact resistance of metal wire, all while conserving time and resources.

Wire bonding could have another method sensitive to reducing bond wire resistance. This is where a thin wire joins two parts of the device using specialized machine. The machine ensures the bond is strong and the wire is placed as optimally as it can be. This generates a shorter path for electricity to flow, which reduces resistance. Just like a shortcut could take you to your destination quicker.

The TS Heating Alloy bond wire resistance has a major impact on the reliability of electronic devices. If the resistance is too great, it can prevent the device from working properly or even cause it to break down altogether. That is especially important for devices that require reliability, such as medical machines or airplanes, where everything must work properly. For failure in these cases, the consequences could be very serious.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.

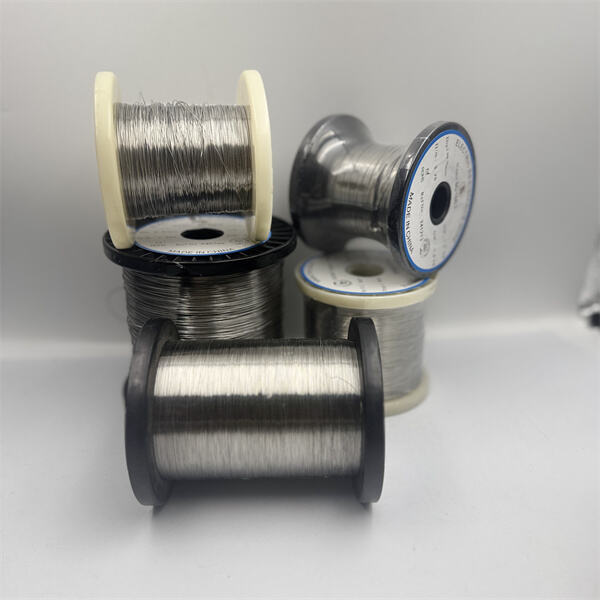

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.