Make wires connecting the world.

When we think about metals, we imagine shiny ones like gold and silver. However, did you ever know that there were so many other kinds of metals around us? Every kind of metal has different properties that allow it to be used for a specific purpose. Kanthal Wire It is one of those types of metal that is highly interesting and has its own utility because of those special features. Read this text to learn about what is kanthal wire; why you should care about it; and why its melting point is something you should keep an eye on. We will speak in simple words and explanations legible for 3rd graders. We need to start with the melting point of metals before we discuss the use of kanthal wire.

Consider the heat we apply to metal as an example. Eventually, it gets hot enough that it melts and flows like a liquid. The melting point, therefore, is the temperature at which this change occurs, at which the metal transitions from a solid state to a liquid state. For kanthal wire, this melting point is extremely high — over 2,000 degrees Fahrenheit! What this means is that kanthal wire can reach very high heat before melting, which is a crucial quality.

Well, that brings us to why kanthal wire’s high melting point is so relevant. Well, this explains why kanthal wire is usually utilized when very high temperatures prevail. Other metals may not be able to endure the heat, and may melt or shatter. Kanthal wire is one of the materials used to make heating elements for ovens and furnaces. If it was being used and the wire melted, it could result in unsafe scenarios like fire hazards or other damage. This is why it is crucial to use a stronger metal like kanthal wire, which has a much higher melting point, in these cases.

So, let’s look into the science of why kanthal wire has a melting point that is so high. That’s because of the way it’s built at the atomic level. Metals consist of little pieces called atoms. In kanthal wire, the arranged in very strong and stable way. This tight arrangement keeps the metal together, even when it gets extremely hot. It's this special quality that makes kanthal wire appropriate for other high-temperature settings, such as the aerospace industry that builds planes and rockets, as well as power plants that create electricity.

Now, even though the kanthal wire is extremely strong and commendable high temp wire, there are few things that affect its melting point. One major factor to look at is how good the wire is. If the wire is incorrect or it is not manufactured with good materials, it may not melt at the appropriate temp as it is supposed. The melting point can also change based on how the wire is used and how often it is heated up. For example, repeated heating and cooling cycles of a wire might influence its high-temperature strength.

There are, however, Products some key tips you should follow to safely use kanthal wire if you do need to do so in a high-temperature application. My first start up is ensure you have the right type of wire for your project. Using the right wire is very important, because various thicknesses of wire have specific melting points. Safety rules Obey all safety rules for your job. That might mean wearing protective gear, such as gloves and goggles and doing the work in a well-ventilated space. Last but not least, you will also want to watch the wire closely as you operate it. In this way, you can ensure that it does not become too hot or melt.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.

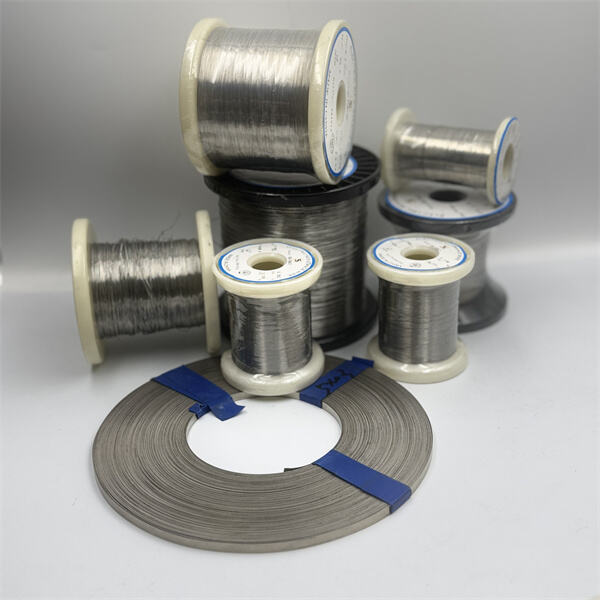

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.